The Dayton Motor 6K157B has gained respect for dependability, efficiency, and long life in service from the commercial to heavy industry. Commonly applied to HVAC systems, industrial machinery, and large-scale fans, this model 6K157B is truly a dependable workhorse. This blog discusses specifications, advantages, common uses, maintenance tips, and other information about Dayton Motor 6K157B that will help you determine whether this unit is suitable for your specific needs.

Dayton Motor 6K157B Overview

The Dayton 6K157B motor applies to general purposes, is designed for continuous duty cycles, and provides outstanding performance in harsh operational environments. This forms part of the wide range of products from the Dayton brand, hence assuring quality and usability at an industrial level. It is manufactured with heavy usage in mind, hence ideal in applications needing sustained power and performance.

Key Characteristics:

- Horsepower: About 1.5, which is a general rating and quite versatile to cover most of the industrial applications.

- Single-Phase: Designed on a 230V single-phase power supply, perfect for most industrial systems of small and medium size.

- Frame Type: Generally in ODP, otherwise known as an open-drip-proof frame, for good ventilation.

- RPM: Runs at 1725 RPM for consistent power output across most applications.

The Dayton 6K157B motor may be close to an ideal solution for equipment requiring continuous, smooth operation due to its simplicity and ruggedness.

Basic Specifications of Dayton Motor 6K157B

Understanding the specifications of the 6K157B motor is important in order to verify whether the requirements of your equipment will be satisfied. Thus, here are the major technical features of the motor:

| Feature | Specification |

|---|---|

| Horsepower | 1.5 HP |

| Voltage | 230V |

| RPM (Speed) | 1725 RPM |

| Frame Type | Open-Drip-Proof (ODP) |

| Phase | Single-Phase |

| Mounting | Foot-Mounted |

| Enclosure | Durable, with optimal ventilation |

Each of these features is evidence that the 6K157B is suitable for long and heavy-duty operations. The ODP frame is good for ventilation, but it requires a location with a clean environment devoid of excessive dust and moisture.

Key Benefits of Using Dayton Motor 6K157B

Dayton Motor 6K157B is characterized by some unique benefits that justify it as one of the best options for application systems that are faced with high demand.

Energy Efficiency

This is where one of the best attributes of the motor are considered: efficiency in using electricity. The 6K157B has been designed to minimize energy wastage through operation with lower energy consumption but an extremely powerful performance.

Built for Heavy Duty

Being strongly constructed, the motor is ideal for use in continuous operations, particularly those industrial settings that require durability. The open-drip-proof construction allows air circulation, which maintains cool temperatures during extended use.

Application Versatility – Reliability of Performance

The motor 6K157B offers consistency in RPM and torque; thus, it is ideal for those applications that require specific continuous operation, including conveyor belts, fans, and HVAC systems.

Low Maintenance and Cost-Effectiveness

Ease of maintenance because of easy accessibility of components reduces idle time and costs spent on the same. Besides, its robustness translates to a longer life; thus, it promises cost-effectiveness in replacement and repairs over time.

Wide Compatibility

With a design that has a foot mount, the motor can be easily integrated into a wide range of systems. In this regard, it presents adaptability and convenience in relation to the compatibility of the industrial setup for a custom equipment configuration.

Uses of Dayton Motor 6K157B

The Dayton 6K157B motor is applied to several uses such as:

HVAC Systems

Due to the stability of the performance and construction durability of the motor, it is ideal for HVAC systems, which stands for heating, ventilation, and air conditioning. The full load rating assures airflow at a constant and adequate volume of 1725 RPM that will be evenly distributed throughout the facility in order to sustain proper temperature control.

Industrial Fans

The Dayton 6K157B motors are installed on many large industrial fans, mostly in factories and warehouses where a lot of air movement is highly needed. This motor allows fans to provide a continuous forceful flow of air that will provide good ventilation.

Pumps

It can be used for driving an industrial water pump in manufacturing or even water treatment plants. It’s reliable in handling continuous duty cycles, and hence, it can be installed in applications requiring consistent flow and pressure.

Conveyors and Material Handling

Due to this, the 6K157B sees its usage in a number of conveyors and material handling machinery. Its reliable RPM and long life meet the consistent demands of a busy manufacturing environment where speed and reliability are critical.

Agriculture Equipment

This motor will also be serviceable for specific agricultural applications, including grain conveyors and other related farm equipment. Consistent performance and the ability to handle outdoor elements make it a very important piece in agricultural operations.

Installation Guidelines for Optimum Performance

Installation is an indispensable activity to ensure optimal performance and a long operating life for the Dayton 6K157B motor. Following are some of the ways to install the Dayton 6K157B motor.

Mount Securely

The motor should be installed on a flat and level surface so that any excess vibrations may not cause wear and tear on it over time. The foot-mounted design makes for easy installation. Still, check each and every bolt and fitting not only for tightness but also for any damage that might have occurred during the transport or storage of the motor.

Check that the power supply to the motor is 230V single-phase. Improper wiring or improper voltages will cause weakness in the motor’s performance and may even burn it up.

Good Ventilation

The motor is ODP (open-drip-proof) frame construction, and since this motor depends on free air for its cooling, it should be installed where there is always good ventilation. Insufficient ventilation may cause overheating, which reduces performance and can lead to damage. It is of essence that airways around the motor are kept free.

The rating of load needs to be appropriate to the motor capacity. Too much overloading of the motor leads to faulty performance, reduces the service life of the motor, and also consequently the malfunctioning of the system.

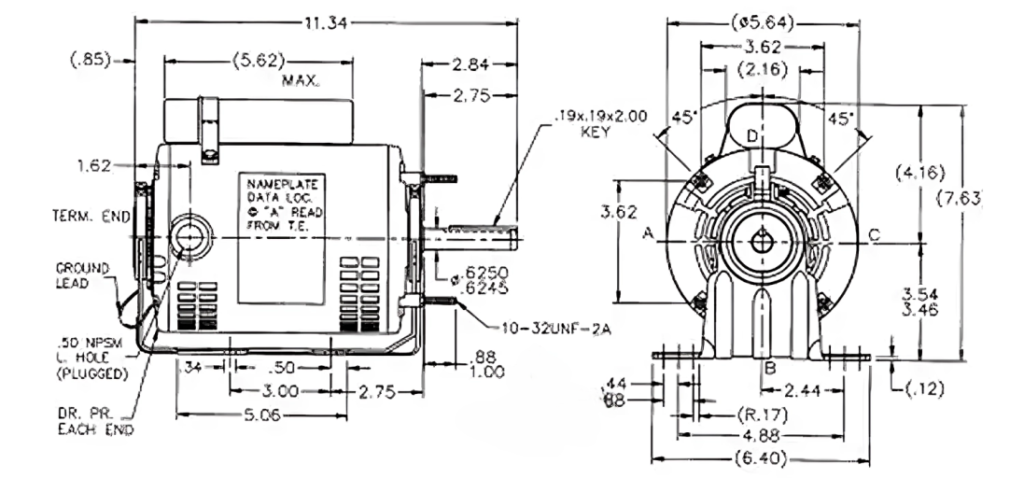

Dayton Motor 6K157B Wiring Diagram

The wiring diagram for Dayton Motor 6K157B has sketched out the minimum a person needs to know in order to connect the motor and operate it safely. These are briefly described below, starting with the key components and their respective connections involved in this motor’s wiring setup.

- Power Terminals: These are the main connecting points by which to attach the AC power supply to the motor. Since this is a dual-voltage motor, it is capable of running on a single-phase power supply that is either 115V or 230V; thus, it utilizes L1 and L2 for connection.

- Contraction of Capacitor: Depending on whether the motor utilizes start or run capacitors, there shall be wires that allow connecting a capacitor in series with the auxiliary winding to assist both the starting torque and smooth operation.

- Ground Connection: The ground terminal is of primary importance concerning safe operation. This terminal is to be connected to ensure that the motor body is to ground, reducing the possibility of electric shock.

- Direction of Rotation: In many wiring diagrams, specific wires (often color-coded) are crossed to obtain reverse rotation.

- Internal Windings (Start and Run): It will also show the main winding which is the run and auxiliary winding, sometimes called the start, which is important in the understanding of the startup and operational stages of the motor.

By following this diagram carefully, one can be assured of efficient and safe operation of the motor.

Maintenance and Troubleshooting Tips

Regular maintenance is a very important way to keep the Dayton 6K157B at the top level.

Routine Inspection

Look for evidence of wear and tear on the motor itself and the surrounding area, and any loose connections that may occur. Small issues will not become major problems if they are corrected at their inception.

Lubrication

Bearings, among others, require lubrication from time to time. The motor should be lubricated according to the manufacturer’s recommendation since lubrication reduces friction and overheating.

Cleaning

Accumulation of dust and dirt in the motor will hamper the flow of air and lead to overheating. Cleaning of the motor and the surrounding area should be done routinely, especially the ones operated under dusty conditions.

Electrical Testing

Periodic electrical tests can be performed to monitor proper voltage input to the motor and its operation within the recommended capacity. In this way, early detection can be done to perform some preventive works.

Avoid Overheating

Thermal protection devices that will provide automatic shutdowns in the motor in case of overheating should be installed. When the motor is constantly subjected to a very high temperature, its capacity to perform will reduce, so some protective devices must be considered for such a high-temperature surrounding.

Some Trouble Shooting Conditions

Even the best of motors, such as the Dayton 6K157B, have developed problems. Some minor issues and how to troubleshoot them are listed below:

- Motor Won’t Start: If the motor would not start, one should check for loose connections, blown fuses, or no voltage. Otherwise, if the wiring appeared good, one should have an electrician analyze the circuit.

- Excessive Vibration: Vibration normally emanates because of either improper mounting or worn-out bearings. These can be solved by tightening mounts and checking bearings.

- Grinding is usually synonymous with worn bearings, and rattling may denote a loose mount. For bearings, lubricate as necessary or replace if worn.

- Overheating: allow proper air circulation around the motor and check for blockages. The motor should be overloaded.

Dayton Motor 6K157B vs Competition

Some comparable models that one could want to consider over the 6K157B motor are highlighted below.

Operation Performance and Efficiency

The power efficiency and reliable RPM of the 6K157B motor match many industrial-grade motors, but often top of the class in ease of maintenance and adaptability.

Price and Maintenance

Generally speaking, Dayton motors are affordable, considering their reputation for durability. The 6K157B requires less frequency in maintenance compared to many of its brands, hence saving the costs of time to time.

Where to Buy Dayton Motor 6K157B

You can purchase Dayton Motor 6K157B from authorized suppliers. Some recommended sources of the motor include:

- Grainger: A trusted source for Dayton products, plus they offer warranties backed by the manufacturer.

- Zoro: It is recognized as the best place to get competitive prices for industrial supplies, such as motors.

- McMaster-Carr: Dependable source for high-quality industrial and commercial equipment.

In making a purchase, ensure it is from authorized dealers to ensure its genuineness and its warranty support.

Conclusion: Why the Dayton Motor 6K157B is a Worthwhile Investment

The Dayton Motor 6K157B is a whole lot more than just a strong motor; it’s an investment in the form of reliability and efficiency for industrial applications. Its robust construction, energy efficiency, and adaptability to use in most settings make it very popular among businesses trying to give themselves an operational upgrade. Installation and maintenance properly will allow you to extend the life of such a motor and ensure that your investment really pays dividends over time.

The Dayton 6K157B motor remains among the highest-rated options for any industry that requires dependable, continued operation, guaranteeing value, quality, and peace of mind.