Introduction

Motors play a fundamental role in driving performance in virtually all applications in the machine and engineering world. From industrial applications to automotive technology, even household appliances, essentially, a motor is a vital part of this mechanism that must be well maintained if it is to serve optimally. However, even the best motors can undergo a process called motor decrepatization after a period of time. The article will discuss what motor decrepatization is, its causes and effects, and some practical ways to prevent it.

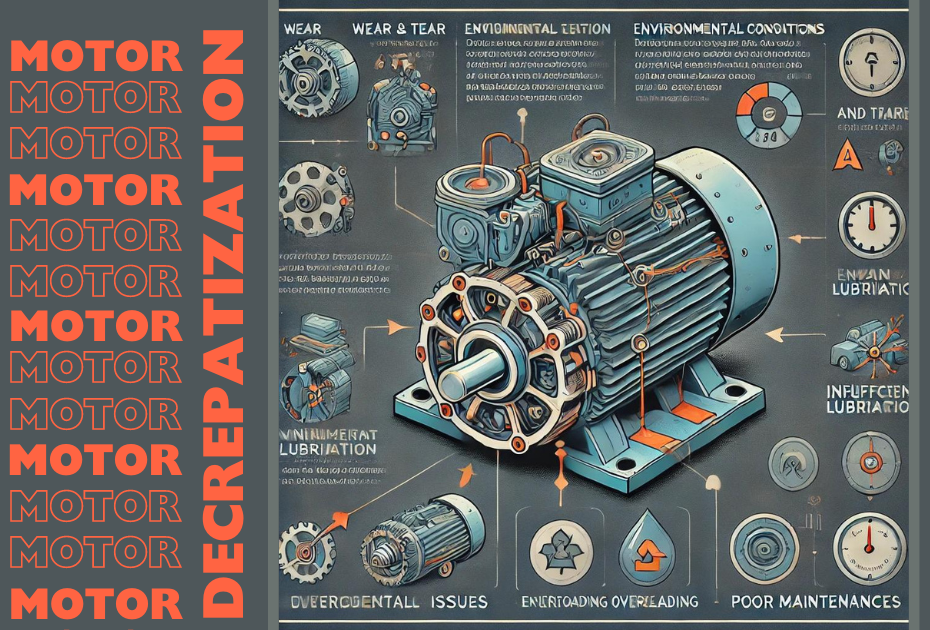

What is Motor Decrepatization?

Motor decrepatization is the slow degradation or wear and tear of the performance and efficiency of motors. It does not happen in a short period or instant, but over a long period as it impairs all kinds of motors, like electric motors, combustion engines, and hydraulic motors. With each turn of the motor, it gets its parts worn out, thereby gradually lowering its efficiency, increasing energy consumption, and ultimately motor failure.

Understanding the Process

The minor wear and tear can be attributed to various operational factors which constitute the actual process of decrepatization. Such minor issues start with the continued functioning of the motor under normal load conditions and compound to cause tremendous performance degradation. Such a phenomenon leads to definite symptoms such as increasing noise levels, overheating, reduced power output, and even mechanical failure.

Causes of Motor Decrepatization

There are various reasons for motor decrepatization, and knowledge of the causes is essential in applying pre-emptive measure.

Wear and Tear

Wear and tear are due to constant motor action. Normally, every moving and fixed part such as the bearings, rotor, or stator suffers frictional stress and wears out gradually. The material degradation may be in the form of surface roughness, misalignment, and increased vibration levels that impair motor performance.

- Types of Wear:

- Surface Wear: It is initiated when two moving parts contact each other resulting in a rough surface.

- Fatigue Wear: This develops from repeated stress and de-stress conditions which may cause cracks.

- Corrosive Wear: This may be due to extreme environmental factors or contaminants.

Environmental Conditions

The longevity of a motor highly depends on its operating environment. Temperature, humidity, or exposure to contaminants usually accelerates decrepatization. Motors operating in an unfriendly environment-the high temperatures, moisture, or chemicals -usually tend to decay much faster.

- Temperature: Expands due to thermal expansion causing misalignment, and increases friction

- Humidity: Moisture may cause the electrical components to rust and corrode.

- Contaminants: Dust and dirt may find their way into motors, clogging and wearing them.

Inadequate Lubrication

Lubrication can be regarded as one of the factors critical in reducing friction among moving parts. Poor or dirty lubrication can cause overheating and rapid wear, which mostly affects the performance of the motor. Lubrication should be done in an appropriate manner to ensure that a motor stays healthy.

- Signs of Poor Lubrication:

- Overheating parts

- High pitch noise levels

- Vibrations and instability

Electrical Problems

Electrical causes can significantly contribute to motor decrepitation. Overheating and overcurrent through poor electrical contacts or a voltage variation imbalance may also lead to a lack of efficiency.

- Common Electrical Problems:

- Voltage Unbalance: It causes irregular heating of the motor windings, and might lead to failure.

- Bad Contacts: Faulty or loose contacts increase resistance owing to corrosion, which may overheat the motor.

Overloading

Overloading of a motor can also increase decrepatization. In this respect, the component is exposed to raised heating effects and tension, which accelerate wear and failure.

- Effects of Overloading

- Energy consumption is increased

- Component life-life reduced

- The possibility of calamitous failure is increased

Shoddy Maintenance Procedures

Irregular maintenance greatly contributes towards decrepatization of the motor. Lack of regular inspection and cleaning procedures exposes the motor towards problems that start small but have a compounded impact on the motor, thus resulting in failure.

- Bad Maintenance

- Breakdowns not expected at a given time

- Higher repair bills

- Less reliability of the overall system

Effects of Motor Decrepatization

Motor decrepatization can be quite harsh as it affects the equipment and the overall system it works within.

Efficiency Loss

The degree of decaying of motor inversely affects its efficiency, bringing along an increase in energy consumption, thereby rising the operational costs. When compared to an efficient motor, an inefficient motor might demand more energy for the production of the same output, and therefore attracts higher electric bills.

- Measuring Efficiency Loss: Depending upon the extent of decrepatization, efficiency loss can lie in the range of 10% to above 30%, making a substantial increase in the cost of operations.

Longer Downtime

Engine decrepatization more often results in unanticipated failures causing equipment downtime, which could have significant cost implications when it happens in an industrial scenario with very tight coordination over the schedules of production.

- Effect on Production: One day of downtime can incur considerable cost and disrupt a production unit.

Increased Repair Cost

Should it be unmonitored, the circumstances it creates most always cause more damage and tends to be costly to fix. Minor issues from wear and tear can be attended to prior so that in the long run, there will not be too much of spending on repairs.

- Cost Implications: It can cost two to three times the routine maintenance costs to repair or replace a motor.

Safety Risks

Defective motors can be dangerous, especially in the industrial field. The consequences of overheating and electrical failure lead to sudden shutdown, causing damage and accidents.

- Safety Precautions: Maintenance and inspection reduce safety risks to allow motors to run effectively and safely.

Prevention of Motor Decrepatization

The prevention of motor decrepatization requires maintenance alongside surveillance. Some of the most effective strategies are listed below:

Regular Maintenance

A routine maintenance schedule must be established so that problems can be identified and solved at the onset. Scheduled inspections, cleaning, and lubrication can provide ongoing optimal performance of the motor.

- Maintenance Checklist

- Inspect and clean motor housing

- Check and replace lubricants as needed

- Tighten loose electrical connections

Lubrication

Install enough lubrication in the motors using the right lubricants. Lubrication level must be checked and used or contaminated lubricant replaced to reduce friction and wearing

- Lubrication Tips

- Use the recommended lubricants of the manufacturers.

- Keep lubrication intervals on the number of operational hours.

Monitoring Operating Conditions

Note environmental conditions which would include temperature and humidity, and all necessary measures to safeguard the motor from a condition that might be hostile to it. Install protective enclosures as needed.

- Environmental Controls:

- Use fans or cooling systems to control temperature.

- Control proper ventilation in enclose spaces

Load Management

Avoid overloading motors by maintaining the manufacturer’s specified load ratings. Incorporate load management practices and spread loads to be distributed over time without stressing the motor.

- Load Monitoring:

- Use load sensors to monitor real time usage

- Implement overloads condition alarms and

Electrical Monitoring

Continue monitoring electrical parameters such as voltage and current and detect abnormal functioning of these parameters. Carry out surge protection and other electrical safeguards for arresting major electrical damage.

- Electrical Maintenance

- Continue to perform electrical audits periodically.

Use protective devices, such as circuit breakers.

- Continue to perform electrical audits periodically.

Training and Awareness

Avail to persons operating and maintaining motors proper training and awareness on best practices of preventing motor decrepatization. Foster a culture of maintenance and care within the organization.

- Training Programs

- Provide regular workshops on motor care

- Distribute motor manuals and guides to staff.

Conclusion

It is a very important problem for any one involved in running and operating maintenance of motors. Now, knowing what causes decrepatization and its effects means that one can apply some preventive measures, which might increase time of operation of motors, reduce their operating costs, and improve their overall performance in general. The strategies used to combat decrepatization entail regular maintenance, proper lubrication, and vigilant monitoring of the motor.

Not only will you safeguard your investment in motors, but you will also improve the safety and productivity of your working environment. When motor health takes a priority position within organizations, following improvements have been achieved: better productivity, reduction of operating cost, and higher reliability.

It is time to start that preventive maintenance program to ensure you have longevity and efficiency in your motors. A basic checkup and commitment to care can literally save you time, money, and headaches down the road.